Page 1 of 2

Quick Jack Option

Posted: Thu Jan 09, 2020 5:06 pm

by 8359

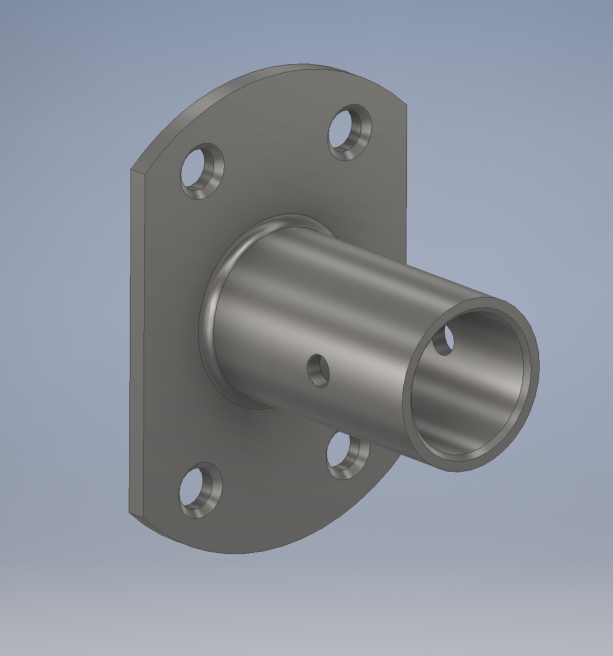

Saw this video the other day, and I think it's a pretty good idea. Got me thinking I could CAD up the plate mounted to the axle pretty easy. I'm going to re-purpose a pitbull motorcycle stand as the jack part. The inner diameter of the tube is 0.860" so it can accept a 1/2" NPT pipe or the end of the pitbull stand.

The design will fit the 120/140/150/170, but certain year models will need the 1/4" holes drilled out to 5/16" and/or 3/8". (Grove

Type 2 but with 1/4" holes).

If you are interested in a set, let me know. I'm by no means trying to turn this into a business, but I figured since I'm doing the leg work I'd offer it up to the forum, makes no difference to me if I order 5 sets or 10. A set of two will be $110 shipped. I'm not making any money off them, this is my cost. I'm having them machined out of 1018 steel. The plate is 1/8" thick and the tube is 3/16" thick. Estimated mass is 0.318 lbs.

Most people who have done something similar have been able to get away with just a logbook entry. This would be considered an owner produced part per the FAA.

Video of operation:

https://www.youtube.com/watch?v=0nnfRKqxTP4

Part:

- 5016-2 Jack Tube.PNG (229.69 KiB) Viewed 4408 times

- IMG_7413.jpg (106.67 KiB) Viewed 4408 times

Re: Quick Jack Option

Posted: Fri Jan 10, 2020 7:33 am

by 8424

That's pretty slick!

May have to talk to the banker (wife) about this!

Steve H

Re: Quick Jack Option

Posted: Tue Jan 14, 2020 5:08 pm

by 8359

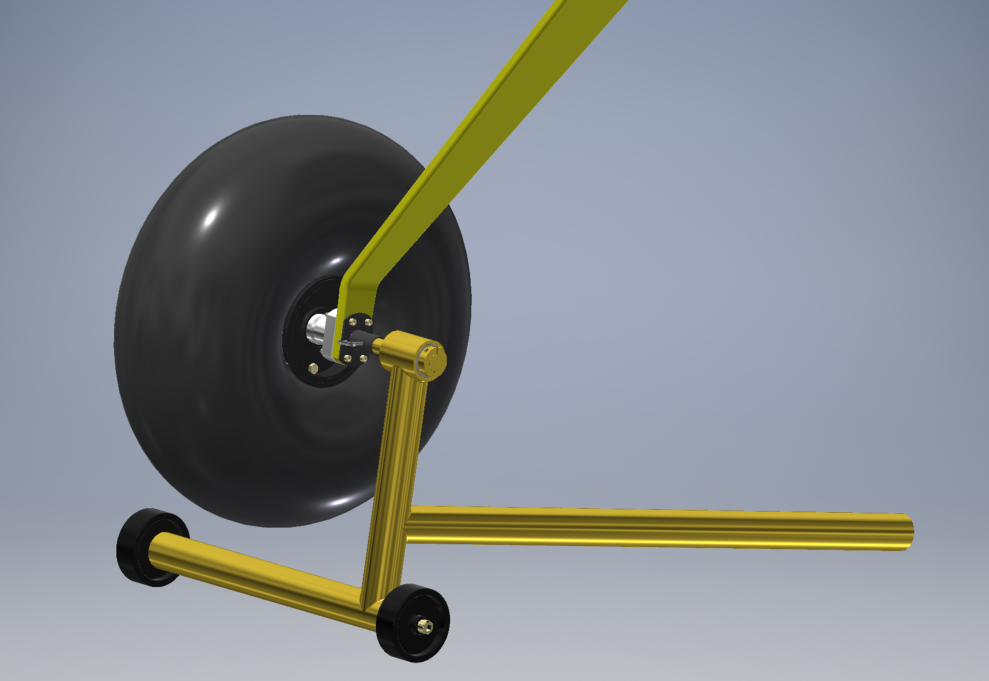

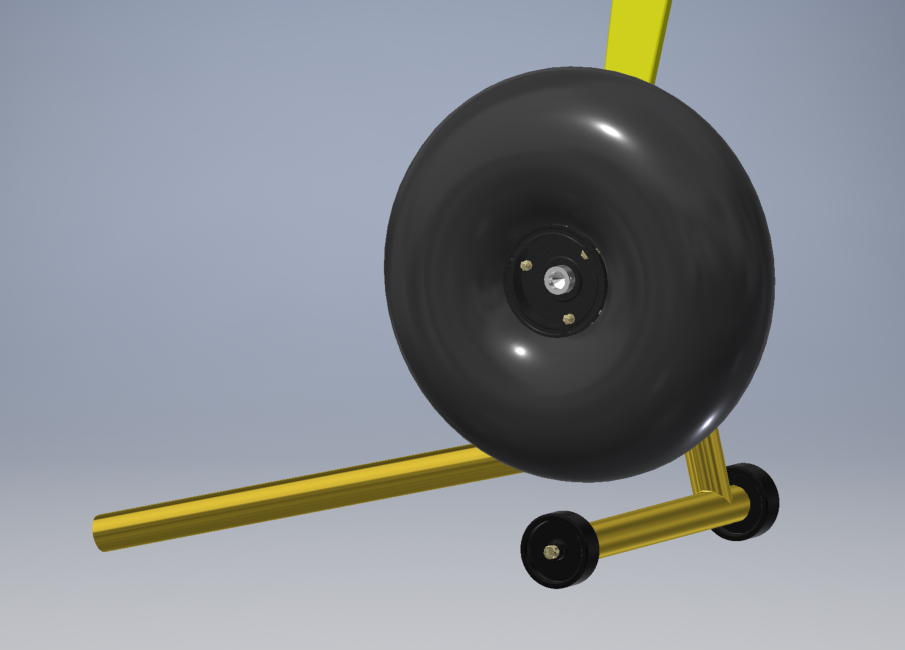

Having some fun with the CAD. Modeled up with the 850 tires currently on my bird..

- C120-Stand-01.PNG (414.17 KiB) Viewed 4299 times

- C120-Stand-02.PNG (351.85 KiB) Viewed 4299 times

Re: Quick Jack Option

Posted: Wed Jan 15, 2020 7:27 pm

by 8233

Looks like a great idea but would you need a 337 to bolt that onto the gear the way it's designed? Just wondering how hard it would be to get approved.

Re: Quick Jack Option

Posted: Wed Jan 15, 2020 7:31 pm

by 8359

A few other people online have welded up a similar bracket. They all installed with just a logbook entry, no 337 or approval. But at the end of the day, I think it would be up to your IA. My thought is you aren’t using different bolts or anything, basically like bolting up a plate washer.

Re: Quick Jack Option

Posted: Wed Jan 15, 2020 8:39 pm

by 6643

Any alteration of the landing gear is a major alteration. So it boils down to whether or not this is an alteration. Personally, I think I'd let it slide. Just make sure you use the same hardware, and get the hole pattern "perfect" and the diameter spot on. If you're using MS20004 bolts I'd use MS20002-C4 washers instead of chamfering the part and having the bolt bear directly on the part, as it does on the gear leg.

Oh, and you're going to need longer bolts.

Re: Quick Jack Option

Posted: Thu Jan 16, 2020 12:36 am

by 8359

Thanks for the insight John.

The bracket has already been sent out, I double and triple checked the bolt pattern prior to sending it out, and I spec'd it with a close fit hole. I've been using the MS20004-28 with 3 washers, so I think I may be able to get away with less washers and the bracket. Too late to ditch the countersink, but I understand your logic in using the C4 washer in counting is as not "major." I guess I can always throw a washer under the bolt head, but it would have has much surface contact with the plate then. Material properties on 1018 vs 4130 (washer) are pretty close, but I guess pretty close doesn't count in aerospace.

Re: Quick Jack Option

Posted: Thu Jan 16, 2020 8:19 am

by 6643

The MS20002-C4 washer is hardened more than an AN960 washer, and has the countersink. (MS20002-4 is the same thing without the countersink.) I'm concerned that if the bolt bears directly on the part the metal will not be hard enough and it will loose tension over time.

Re: Quick Jack Option

Posted: Sat Feb 22, 2020 6:36 pm

by 8359

I had a long biz trip after the parts arrived and wasn't able to install until this weekend. It turned out great! The motorcycle stand could use a little longer lever arm to get it over easier, but that's an easy fix. It does lift it way higher that I need to service the tire/brakes, but that gives me some room if I end up with bigger tires. I took John's advice and used the C4 washer under the head and only needed one under the nut.

I have 5 more sets I'm selling at my cost if anyone else wants a pair.

Re: Quick Jack Option

Posted: Sat Feb 22, 2020 7:37 pm

by 6643

Nice!